Spare Parts Inventory Management Software That Works

Introduction to Spare Parts Inventory Management

In the world of industrial operations, the importance of spare parts inventory cannot be overstated. Spare parts inventory management is the backbone of ensuring operational continuity and efficiency. When machinery breaks down or components fail, having the right spare parts readily available can prevent costly downtime. This article delves into the intricacies of spare parts inventory management, exploring the strategies and tools that can help businesses maintain optimal operations.

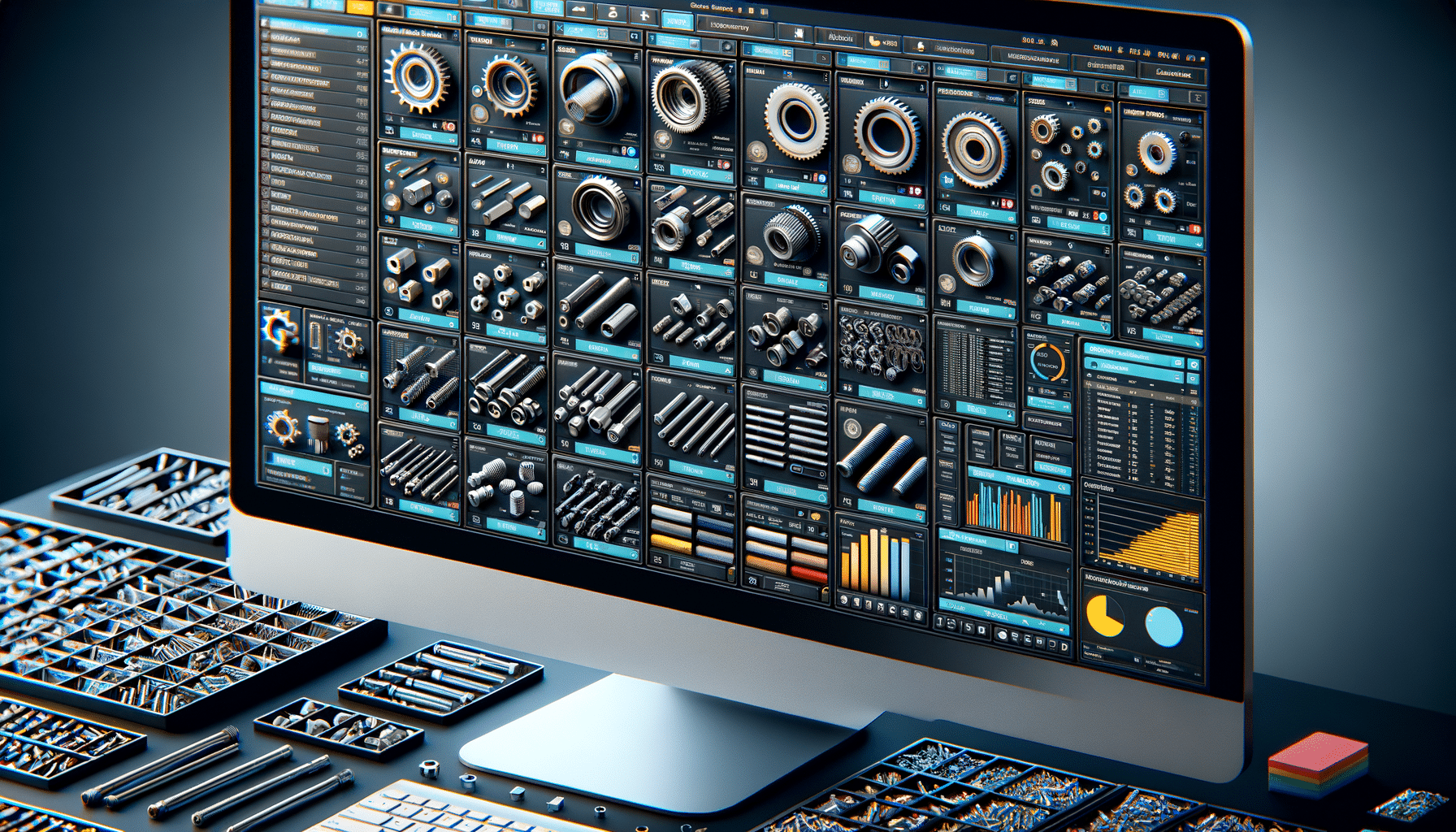

The Role of Technology in Inventory Management

Technology plays a pivotal role in modern spare parts inventory management. With the advancement of digital solutions, businesses can now leverage inventory management software to streamline their operations. These systems offer a range of functionalities, including real-time tracking of inventory levels, automated reordering, and detailed analytics. By integrating technology into their inventory processes, companies can achieve greater accuracy and efficiency, reducing the risk of stockouts or overstocking.

Some key benefits of using inventory management software include:

- Real-time visibility into inventory levels

- Automated alerts for low stock

- Improved forecasting and demand planning

- Enhanced reporting capabilities

Strategies for Effective Spare Parts Inventory Management

Effective spare parts inventory management requires a strategic approach. Companies must balance the need for availability with the cost of holding inventory. One strategy is to categorize parts based on their criticality and usage frequency. High-priority parts should be readily available, while less critical items can be ordered as needed. Additionally, implementing a just-in-time (JIT) inventory system can minimize excess stock and reduce storage costs.

Another strategy involves regular audits and reviews of inventory levels to identify slow-moving or obsolete parts. By regularly assessing inventory, businesses can make informed decisions about which items to keep in stock and which to phase out.

Challenges in Spare Parts Inventory Management

Managing spare parts inventory is not without its challenges. One common issue is the unpredictability of equipment failures, which can lead to sudden spikes in demand for certain parts. Additionally, the wide variety of parts required for different machinery can complicate inventory management, making it difficult to maintain accurate records.

Another challenge is the potential for human error in manual inventory processes. Without the right tools and systems in place, businesses may struggle with inaccurate data, leading to stock discrepancies and inefficiencies. Overcoming these challenges requires a combination of technological solutions and robust processes to ensure accuracy and reliability.

Conclusion: Achieving Operational Excellence

In conclusion, effective spare parts inventory management is essential for businesses aiming to achieve operational excellence. By leveraging technology, implementing strategic inventory practices, and addressing common challenges, companies can ensure they have the right parts available when needed. This not only minimizes downtime but also contributes to cost savings and improved operational efficiency.

As industries continue to evolve, staying ahead in inventory management will be crucial for maintaining a competitive edge and ensuring the smooth functioning of operations.